Minicam, a portfolio company of Halma plc, specialise in the manufacture of robotic pipeline inspection systems and required specialist facilities to house their production, research and development, and office functions. Previously split across three buildings, Minicam’s teams were disconnected and lacked awareness of other disciplines across the company. Minicam used their relocation to transform the way their teams operate - bringing all elements of the group under one roof with the aim of helping the business to become more collaborative. The investment in their new headquarters is a big step for the company and is designed in line with their future growth plans.

LOCATION / MANCHESTER M38

-

SECTOR / MANUFACTURING

-

SIZE / 38,500 SQ FT

-

DURATION / 13 WEEKS

LOCATION / MANCHESTER M38 - SECTOR / MANUFACTURING - SIZE / 38,500 SQ FT - DURATION / 13 WEEKS

Stage 1: defining the project goals

THE MISSION STATEMENT

Minicam tasked us with creating a workplace environment to foster an innovative ecosystem where all aspects of the business work harmoniously, with a contemporary, industrial look to reflect the nature of their work. The new space completely re-imagines the way their teams work and will transform their company culture by creating a community feel and enabling knowledge sharing.

Stage 2: deVELOPING THE LAYOUT

“THE NILE CONCEPT”

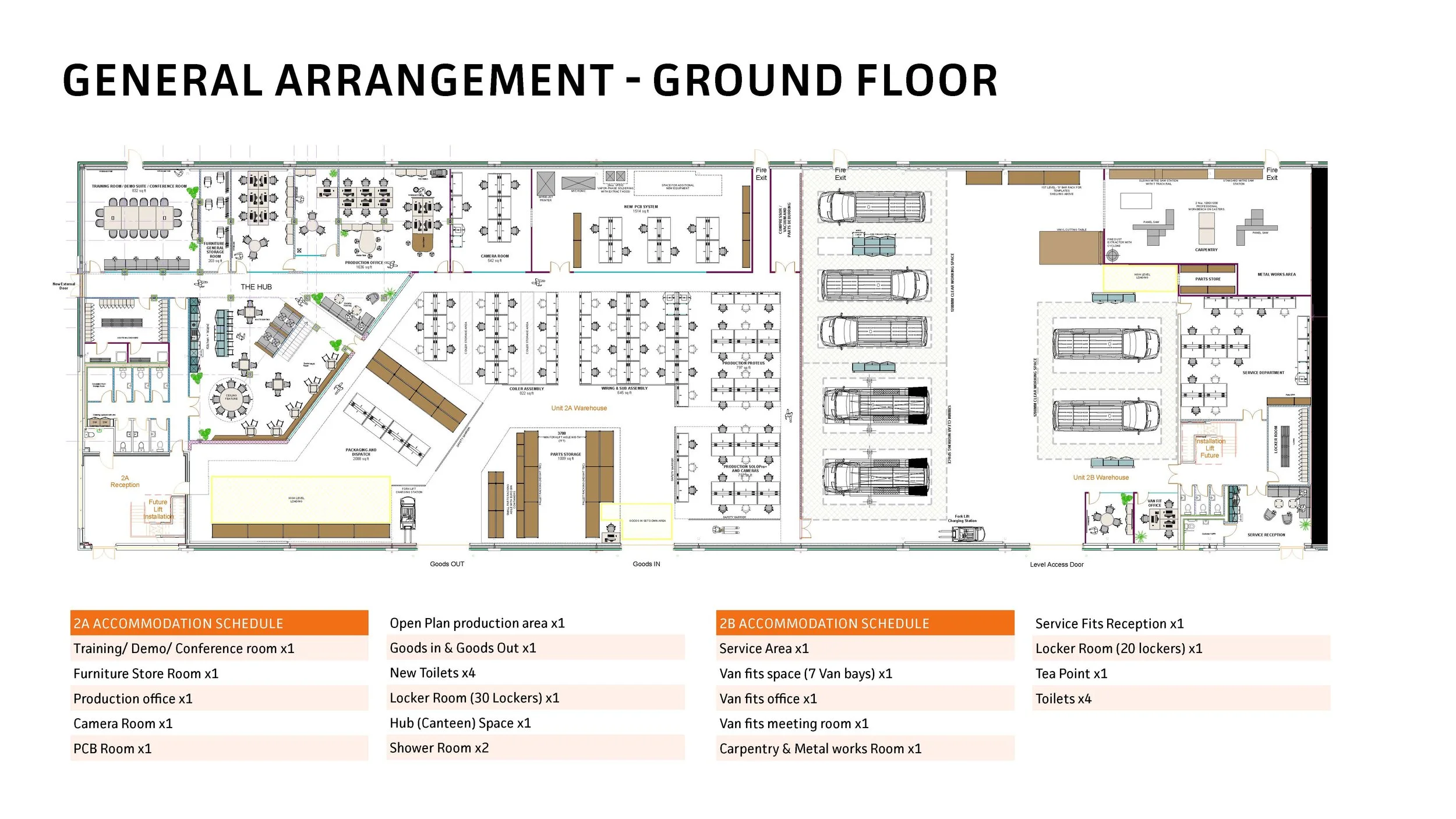

The layout is Inspired by the river Nile and the way the river functions as an important transportation and trade route, connecting town along the water’s edge. IN The Minicam fit out, a main circulation route that snakes through the warehouse connects all the different departments. Users can follow the product journey through the facilities and learn how Minicam design, develop, and produce their products, while also gaining insight into their brand. Each and every area of Minicam’s new space is connected to their process and product, creating an all-encompassing experience of their brand and business

Stage 3: developing the design

INITIAL VISUALS

Stage 1: defining the project goals

FINAL DESIGN

Minicam tasked us with creating a workplace environment to foster an innovative ecosystem where all aspects of the business work harmoniously, with a contemporary, industrial look to reflect the nature of their work. The new space completely re-imagines the way their teams work and will transform their company culture by creating a community feel and enabling knowledge sharing.

Visual connectivity

The double-height social space offers multiple viewing decks and a large glass façade that overlooks the production facilities – representing the transparency which is at the heart of Minicam’s company culture. A 12m high stud wall separates the production and office space, while also creating opportunities for visual connection. Standing in the office, a 4m high platform offers views over the production space; this concept it carried through to overhanging meeting rooms which also look out onto other workspaces.

Nurturing culture

Previously, Minicam’s staff had nowhere to come together for lunch and socialise; our solution was The Hub, a refuge and key connector of Minicam’s workplace. Staff are rewarded with a fully equipped kitchen, communal seating, and space to relax away from their workstations. The open layout also allows for townhall meetings and events.

“James Sargeant is a credit to the organisation. When we had some dark moments during the job, James’ communication to us was really strong and reassuring. Since we have moved in we have had countless visitors wowed by the design.”

— tom davies, managing director, minicam

Pushing design boundaries

The increase in production space has allowed Minicam to invest in state-of-the-art manufacturing machines, alongside additional R&D facilities which will help them to remain the market leader with new and innovative products. This complex fit out pushes the boundaries of workplace design; a unique solution that brings together manufacturing and traditional office space to help Minicam achieve a more united business, carry out all operations from one site, and improve production efficiencies.